BLENDED PRODUCTS UNVEILS VECO₂: THE WORLD’S FIRST VEGAN CERTIFIED ANAEROBIC DIGESTION (AD) CARBON DIOXIDE

Brigg, North Lincolnshire – Blended Products is proud to announce that its Anaerobic Digestion Carbon Dioxide – VeCO₂, has been officially certified as vegan by the Vegetarian Society. This milestone marks VeCO₂ as the first-ever carbon dioxide product to receive the prestigious Vegan accreditation from the Vegetarian Society.

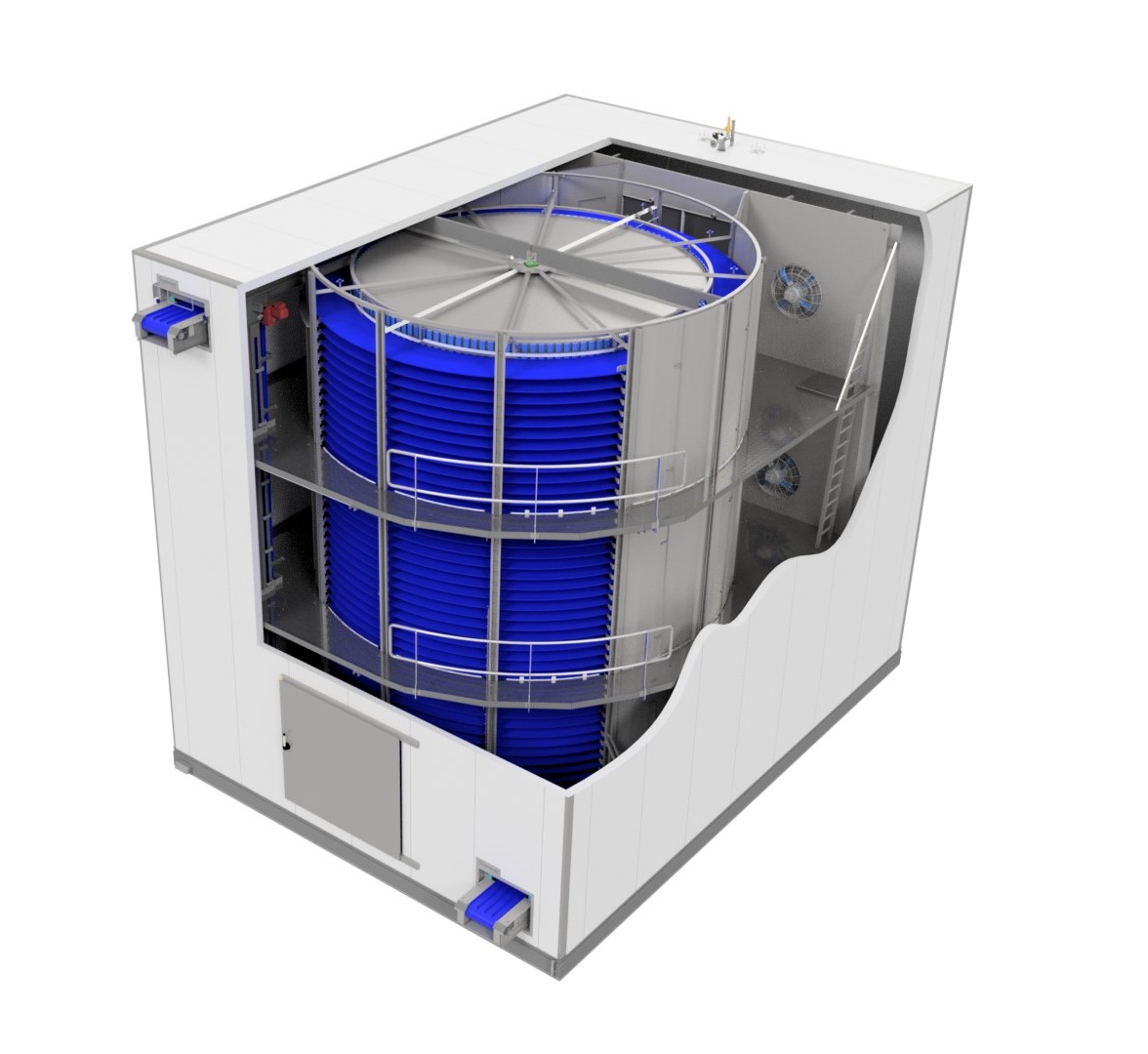

Partnering with a UK-based AD plant, Blended Products VeCO₂ is made from plant-based matter. This sustainable technology is not only an eco-friendly alternative to traditional carbon dioxide sources, but it is also the first-ever carbon dioxide product to be recognised by the Vegetarian Society as fully vegan certified.

VeCO₂ enables businesses to operate more sustainably by providing an ethical, plant-based CO₂ alternative that supports both environmental and operational goals.”

In collaboration with a dedicated working group of leading experts from the biogas and carbon capture sectors, Blended Products has been actively driving progress in these fields. Partnering with a UK-based AD plant, the company has developed this innovative product. “VeCO2 enables businesses to operate more sustainability by providing an ethical, plant-based CO2 alternative that supports both environmental and operational goals” said Caroline Hunter, Head of Commercial at Blended Products Ltd. “By opting for VeCO₂, businesses can lessen their dependence on fossil fuel-derived CO₂ and support a more sustainable future.”

The Vegetarian Society’s vegan certification guarantees that VeCO₂ is produced without any animal-derived inputs, making it an ideal choice for industries and consumers prioritising ethical and sustainable solutions. This certification provides additional reassurance to businesses seeking to reduce their environmental impact without compromising on their vegan and cruelty-free standards.

VeCO₂ offers a cleaner, greener, and more sustainable alternative to traditional CO2 sources, and its certification sets a new benchmark for eco-conscious innovation in the industry. As a versatile and highly effective product, VeCO₂ is suitable for a wide range of applications, particularly food and beverage processing. VeCO2 supports businesses aiming to reduce their Scope 3 emissions, offering a certified sustainable CO2 alternative for various industries.

For more information about VeCO₂ and its Vegan Certification, please visit www.Blendedproducts.com contact Blended Products at 01652 680555

About Blended Products.

Blended Products is an established supplier of specialty gases and liquids across the UK to a range of industries. Sustainability Todays “Chemical and Gases Company of the Year 2025”.

About the Vegetarian Society

The Vegetarian Society is a UK-based charity that has been promoting vegetarian and vegan living for over 170 years. Its Vegan Certification mark guarantees that products meet strict vegan criteria, offering consumers an assurance of quality and ethical production.

Media Contact:

Charley Christopher

Marketing Manager

Blended Products

07538025030

Charlotte.christopher@Blendedproducts.com

www.blendedproducts.com

END