Feb 12th, 2026

Feb 12th, 2026

5 mins

5 mins

Maintaining high standards of hygiene, safety and product integrity is essential in frozen food operations. Whether handling pallets, crates, drums or bulk ingredients, every movement within a cold store must support compliance with recognised food safety frameworks such as BRC, HACCP and individual retailer specifications.

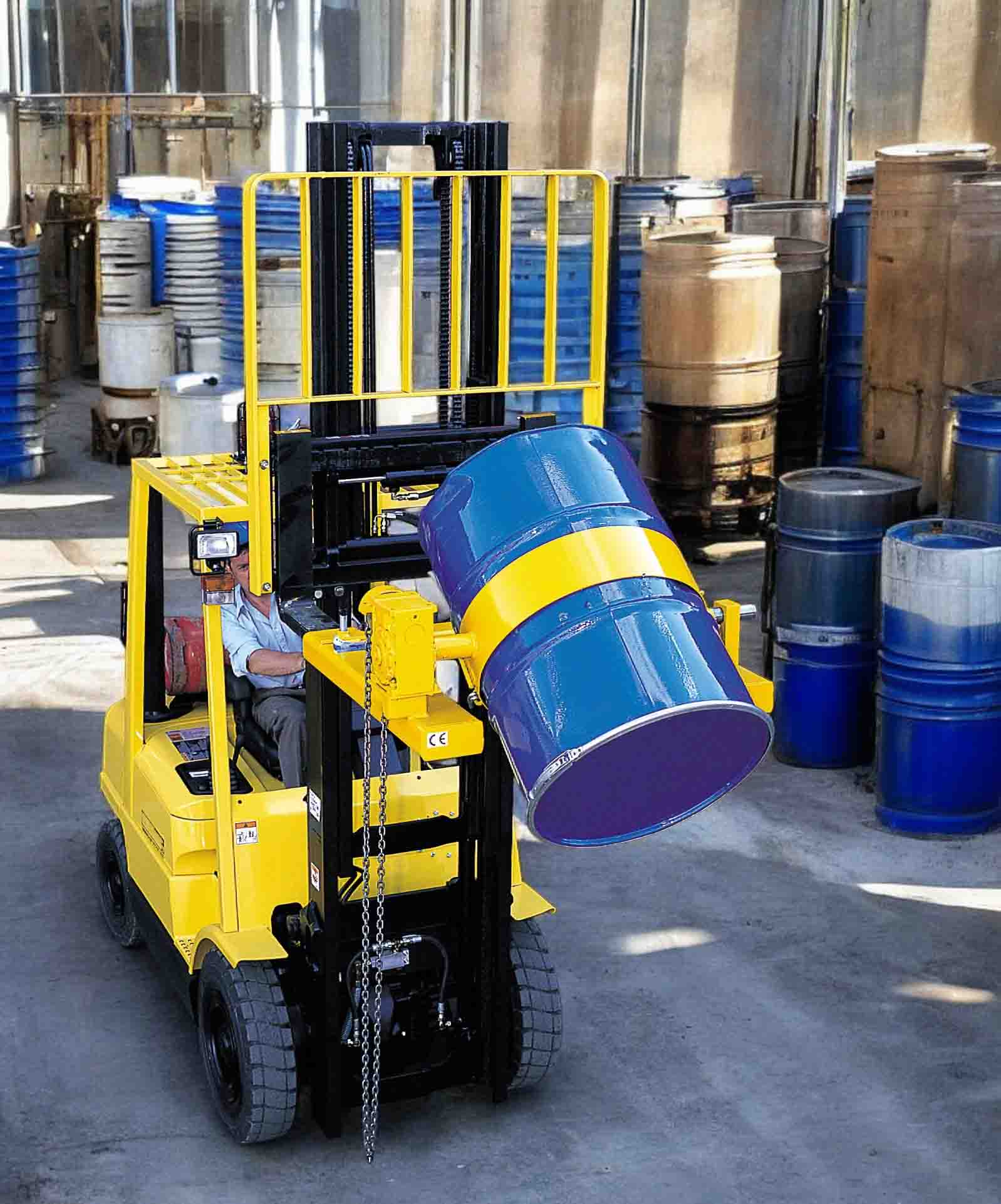

Forklift attachments play a surprisingly important role in meeting these standards. By improving hygiene, reducing contamination risks and supporting controlled, consistent handling, the right attachments help cold store operators stay compliant while protecting both staff and products.

Supporting BRC Standards Through Hygienic Design

BRC Global Standards place strong emphasis on cleanliness, contamination control and equipment suitability. Forklift attachments designed specifically for food environments directly support these requirements by offering:

- Stainless steel or food‑safe finishes that resist corrosion and withstand frequent washdowns

- Smooth, sealed surfaces that prevent debris build‑up and make daily cleaning easier and more effective

- Hygienic, easy‑to‑clean designs that help keep bacteria and allergens at bay

With UK‑manufactured quality and in‑house engineering expertise, Contact Attachments can also provide bespoke configurations to ensure equipment aligns precisely with site‑specific hygiene and compliance needs.

Reducing Contamination Risks in Line with HACCP Principles

HACCP requires businesses to identify and control potential hazards throughout the handling process. Forklift attachments help reduce several key risks:

- Minimising manual contact with loads, lowering the chance of cross‑contamination

- Preventing product damage, which can expose contents and create hygiene issues

- Ensuring consistent, controlled handling to reduce the likelihood of spills or compromised packaging

Attachments such as clamps, rotators and drum handlers allow operators to move products safely and predictably, supporting the preventive approach at the heart of HACCP.

Meeting Retailer Specifications for Safety and Traceability

Major retailers often set additional requirements around hygiene, product integrity and operational control. Attachments engineered for cold‑store environments help meet these expectations by offering:

- Cold‑store‑rated hydraulics for reliable performance at sub‑zero temperatures

- Pressure‑controlled handling to protect fragile frozen packaging

- Operator‑friendly controls that improve accuracy and reduce the risk of mishandling

- Compatibility with traceability systems, ensuring products remain intact and identifiable throughout the chain

By reducing damage, contamination and downtime, the right forklift attachments help cold‑store operators maintain the high standards demanded by BRC, HACCP and leading retailers.

Contact Attachments Ltd has been supporting UK manufacturers for over 50 years and offers a wide range of standard and bespoke material‑handling solutions for the food and drink sector. To discuss how the right attachment can support compliance in your chilled or frozen operations, or to arrange a review of your current setup, contact the team on 01686 611200 or visit www.forklift-attachments.co.uk.