Feb 12th, 2026

Feb 12th, 2026

9 mins

9 mins

The frozen food industry operates in one of the most hostile working environments on Earth. Necessarily well below minus 18 degrees, with many facilities at minus 25 degrees, visibility is often reduced by fog or breath, huge mechanical plant is running, and forklifts share space with pedestrians.

For decades, the industry has viewed Safety and Efficiency as two opposing forces.

If you want to be safer, you generally have to slow down. You add more checks, you introduce rigid exclusion zones, you limit shift times. Safety is traditionally viewed as a cost center—a necessary insurance policy that protects staff but taxes productivity.

But a shift in technology is flipping this equation. By digitising the warehouse for efficiency, we are finding that world-class safety features are appearing not as an extra cost, but as a “free bonus.”

The Eyes That Don’t See Faces

The biggest barrier to adopting digital monitoring in warehouses has always been the “Big Brother” fear. No worker wants a camera watching their every move, and GDPR regulations make recording people a legal minefield.

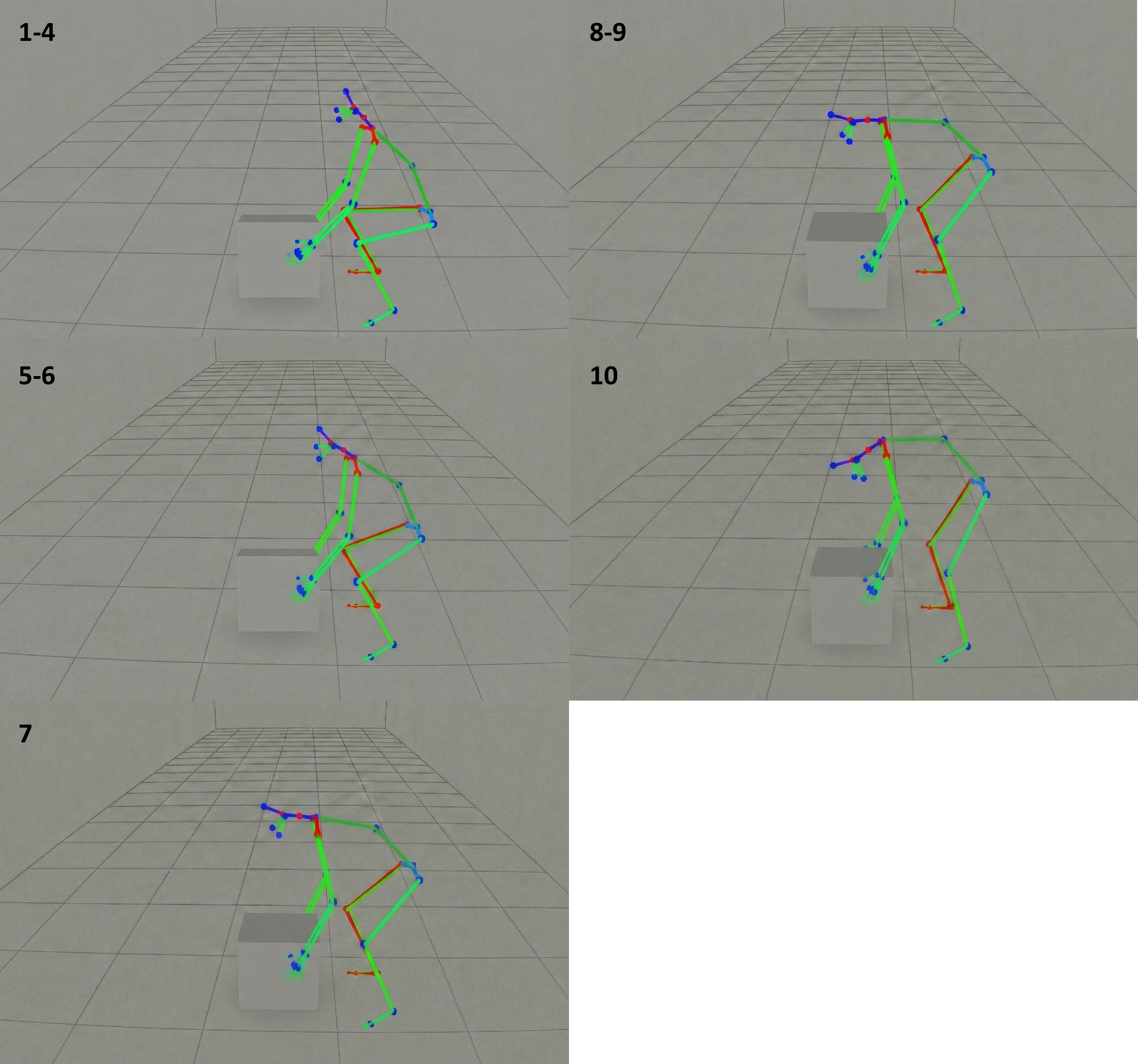

Darkonium have solved this through a “Skeletonisation” process . In this setup, the AI system processes the video feed instantly and discards the image of the person. Instead, it extracts a simple “stick figure” representation of their joints and movements.

It doesn’t know who the worker is; it only knows how the worker is moving.

This technology was originally developed to detect fallen passengers on buses, but it’s also a lifesaver in a freezer.

Use Case 1: The “Man Down” Event

In a loud, foggy aisle at these temperatures a slip or a medical episode can go unnoticed for dangerous amounts of time.

A static camera requires a security guard to be looking at the right screen at the right moment and colleagues may be in busier areas.

An AI looking at “skeletons,” however, never blinks. It understands posture. It instantly recognizes the difference between a worker tying their shoelace and a worker who has fallen and not moved for 30 seconds. It can trigger an alert immediately, dispatching help to the exact aisle.

The beauty of this? The same system tracking that skeleton for safety is also calculating optimal pick-rates for efficiency. One system, two benefits.

Managing the “Cold Dose”

Hypothermia and cold stress are silent risks. Traditionally, we manage this with rigid schedules: 45 minutes in, 15 minutes out.

But this static approach is flawed. “45 minutes” feels very different if you are vigorously stacking pallets versus waiting still in a cold draft because of a bottleneck.

Use Case 2: Dynamic Exposure Tracking

By combining digital tracking with a physiological model, we can move from counting minutes to measuring the actual “Cold Dose.”

The system can recognise that a worker has been stuck in a high-airflow zone waiting for a forklift. Even if they have only been inside for 20 minutes, their “Cold Dose” might be critical because they haven’t been generating body heat through movement.

The AI can alert the shift manager to rotate that specific worker out early. Conversely, it might safely extend the shift of a worker who is in a warmer zone and moving actively. This ensures worker health is protected based on biological reality, not just the clock, while maximising the available labor hours.

Predicting the Black Ice

Slips and trips remain the number one or number two cause of accidents in our sector. In a freezer, this is almost always a result of ice buildup—usually caused by humid air entering through doors and settling on cold floors.

Usually, we deal with this reactively. Someone spots the ice, or worse, slips on it, and then we clean it.

Use Case 3: Predicting the Hazard

A Digital Twin of your facility doesn’t just track boxes; it tracks thermodynamics.

If a dock door is held open for 20 minutes on a humid July day, the system knows exactly how much moisture has entered the air. It knows the airflow patterns of your facility. Therefore, it can calculate exactly where that moisture will settle and freeze.

It can warn the maintenance team: “Ice formation likely in Aisle 4, Bay 2 in the next 30 minutes.”

You can salt or scrape the floor before the ice even forms. This is the ultimate goal of safety: moving from reacting to accidents to preventing the conditions that cause them and of course it also retains the area as a productive environment keeping the optimum routes open and available at all times to maximise productivity.

The Bottom Line

The fascinating thing about these three examples is that they all run on the same infrastructure used to optimize energy and throughput.

- The cameras used for “Skeletonisation” are the same ones tracking inventory movement.

- The data used for “Cold Dose” management is the same data used to optimise labor routing.

- The thermal model predicting ice is the same model used to save money on compressor electricity.

In the new digital reality, you don’t have to choose between being fast and being safe. By deploying smart, privacy-compliant AI, you protect your margins and your people at the same time.

By Robert Sugar, Founder of Darkonium AI

Robert Sugar is the founder of Darkonium, a British startup and member of the British Frozen Food Federation. Darkonium specialises in helping manufacturers and logistics providers transition from static planning to dynamic, AI-assisted efficiency and safety.